Barley fodder management for livestock production among smallholder farmers [Uganda]

- Creation:

- Update:

- Compiler: Sarah Babirye

- Editor: Kamugisha Rick Nelson

- Reviewers: Nicole Harari, Udo Höggel, Donia Mühlematter

Balle

technologies_3453 - Uganda

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Key resource person(s)

SLM specialist:

Kabanda Fred

0794661269

Kyanja Agricultural Resource Centre

Kyanja Agricultural Research Organizations Gayanza Road ,Parish P.O BOX 7010,KAMPALA

Uganda

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Scaling-up SLM practices by smallholder farmers (IFAD)Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

National Agricultural Research Organisation (NARO) - Uganda1.3 Conditions regarding the use of data documented through WOCAT

When were the data compiled (in the field)?

29/1/2018

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

Comments:

The technology is not problematic with regard to land degradation

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

Barley fodder technology is a livestock feed that grows under a hydroponic system. This green feed is highly palatable, rich in protein and energy yet cost-effective. It takes few days to maturity (5-6 days) and can be grown in a smaller area. One kilogram of barley seeds can yield up to 6 to 6.5 kg of green feed.

2.2 Detailed description of the Technology

Description:

Barley is a cereal grain that grows with hydroponic system to supplement on the feeds for livestock. This system enables crops to grow without soil so easily yet they mature within the shortest time in a smaller area. It is commonly used in finishing rations for livestock. Barley sprouts the best, grows the fastest and is cost-effective. This green feed is less expensive yet highly palatable and nutritious for animals.

To work well for sprouted fodder, the barley seed needs a high germination rate. Sprouting barley consistently and economically needs a climate-controlled space, light (18 hours of light and 6 hours of darkness) and a watering system. The ideal temperature being 75 degrees F and 70% humidity. Air movement is necessary to control mold.

The technology ensures a reduction of pesticides and herbicides because the plants are in a protected environment . The sprouts are high in protein and fiber, and are naturally balanced in protein, fat and energy. Barley fodder has 95% of the energy and higher digestibility hence reducing the occurrence of digestive diseases, such as bloat. It is one of the most nutritious sprouts and is full of essential nutrients, vitamins and minerals. These are absorbed more efficiently due to the lack of enzyme inhibitors in sprouted grain. Dry barley seeds yields between 6-6.5kg of green feed. Feeding barley fodder will improve the overall health and wellbeing of animals. With this technology, farmers can easily anticipate the expected amount of feeds. Despite the benefits, growing barley requires skills, knowledge and constant supervision especially maintaining the conditions required. Barley seeds are at times hard to get. In case of commercial/large livestock farming, the technology is not economically feasible. Bacterial and fungal growth is also another challenge like the common bread mould therefore seeds must be sterilized. The steps taken to grow barley seeds are as follows:

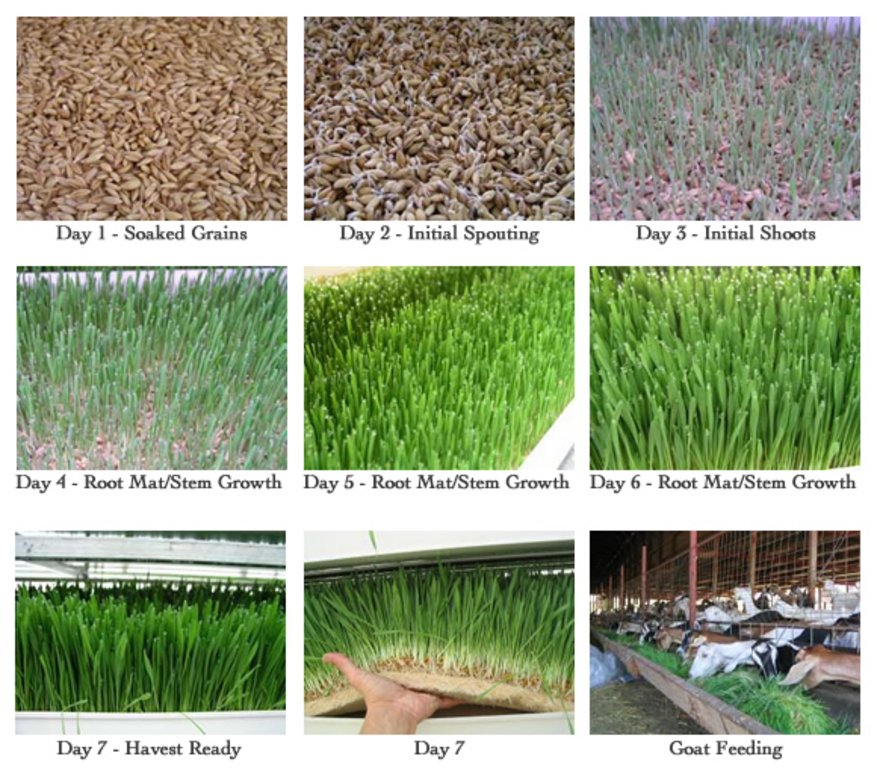

•On day 1, the barley seeds are laid on plastic trays after being soaked in water for 8-12 hours or an overnight. These seeds must be moist and kept clean. In case of any moulds, hydrogen peroxide may be used in the soaking water to kill mould.

•On day 2, the trays are placed on shelves where they are stacked. On this day, initial sprouting begins. Seeds must be kept moist, but not water-logged. Manually, water should be spread every after 4-5 hours. The seeds will usually sprout within 24 hours.

•On the third day, initial shooting begins. Watering still proceeds.

•From the 4-5th day, the root mat or the mat stem begin to grow.

•On the 6-7 the day, the farmers begins to harvest the barley grass and gives to the livestock. The grass has produced a 6-8 inch high grass mat with a 2 inch mat of interwoven roots.

The sprouted grain is harvested by removing the tray or sliding the mat off the tray in one long sheet. The mats can be cut to the appropriate size and fed to animals. Livestock will eat the whole thing like seeds, roots, and grass therefore, there is minimal waste. Barley is a major feeding option when pastureland and/or hay are in short supply, or adds a highly nutritious and relished supplement to traditional grazing.

Initial costs involved to a small scale farmer are minimal. This includes buying clean seeds, 5 kg costing 15,000/=, 10 plastic trays (50000), 2 watering cans (20000), 1 bucket for soaking seeds (10000), watering seeds 6 times (18000), soaking seeds (3000), labour for making shelves (30000), papyrus mat (20000) ,2 kg of nails (10000), timber for making shelves (50000), chopping ready folder (3000) totalling to 232,000/= for a start. However, this depends on the amount of fodder a farmer wants to produce.

A kg of barley seeds yields to 7-10 kg of green fodder. Each kg of fodder is sold at 1500 hence in a kg planted (i.e. 3000 invested), a farmer is likely to earn 15000/=

The technology is advantageous in that there is little or insignificant costs involved on maintenance of the technology. Maintenance only involves daily watering of seeds (18000 for 6 days), cleaning the treys after use (3000) and supervision on barley during growing for 6 days (18000) totaling to 39000/=.

2.3 Photos of the Technology

2.4 Videos of the Technology

Date:

29/01/2018

Location:

Kyanja Agricultural Resource Centre

Name of videographer:

Babirye Sarah

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

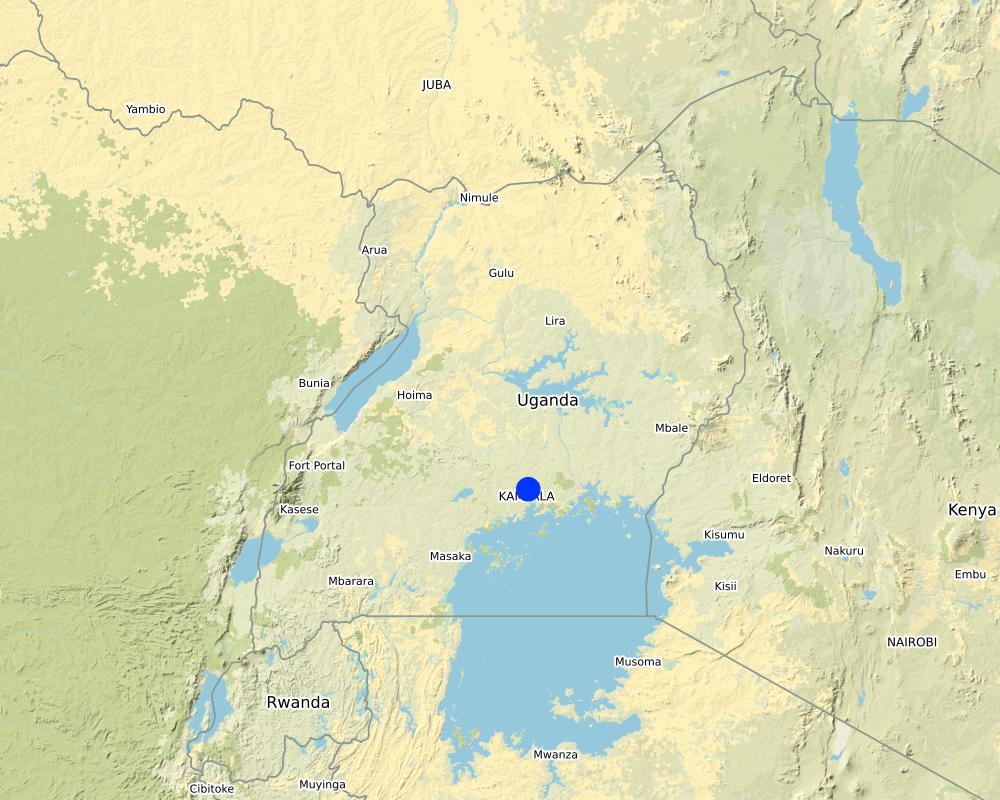

Country:

Uganda

Region/ State/ Province:

KAMPALA

Further specification of location:

Kyanja, Gayaza

Map

×2.6 Date of implementation

If precise year is not known, indicate approximate date:

- less than 10 years ago (recently)

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- during experiments/ research

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- create beneficial economic impact

3.2 Current land use type(s) where the Technology is applied

Other

Specify:

Laboratory

Remarks:

The demonstration was done at Kyanja National Research Organization in a laboratory.

3.3 Further information about land use

Water supply for the land on which the Technology is applied:

- mixed rainfed-irrigated

Comments:

Water can be collected from national water (water supplied to people by the government of Uganda, National Water and Sewage Cooperation). Water from rainfall is be used in the process.

Specify:

Not seseonal, can be grown any time

3.4 SLM group to which the Technology belongs

- integrated crop-livestock management

- minimal soil disturbance

3.5 Spread of the Technology

Specify the spread of the Technology:

- applied at specific points/ concentrated on a small area

Comments:

Basically after building a structure with shelves, barley seeds are planted into trays.

3.6 SLM measures comprising the Technology

management measures

- M2: Change of management/ intensity level

Comments:

Barley seeds are cleaned before being planted to avoid the risks of fungal attack e.g moulds

3.7 Main types of land degradation addressed by the Technology

other

Comments:

Not applicable

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- not applicable

4. Technical specifications, implementation activities, inputs, and costs

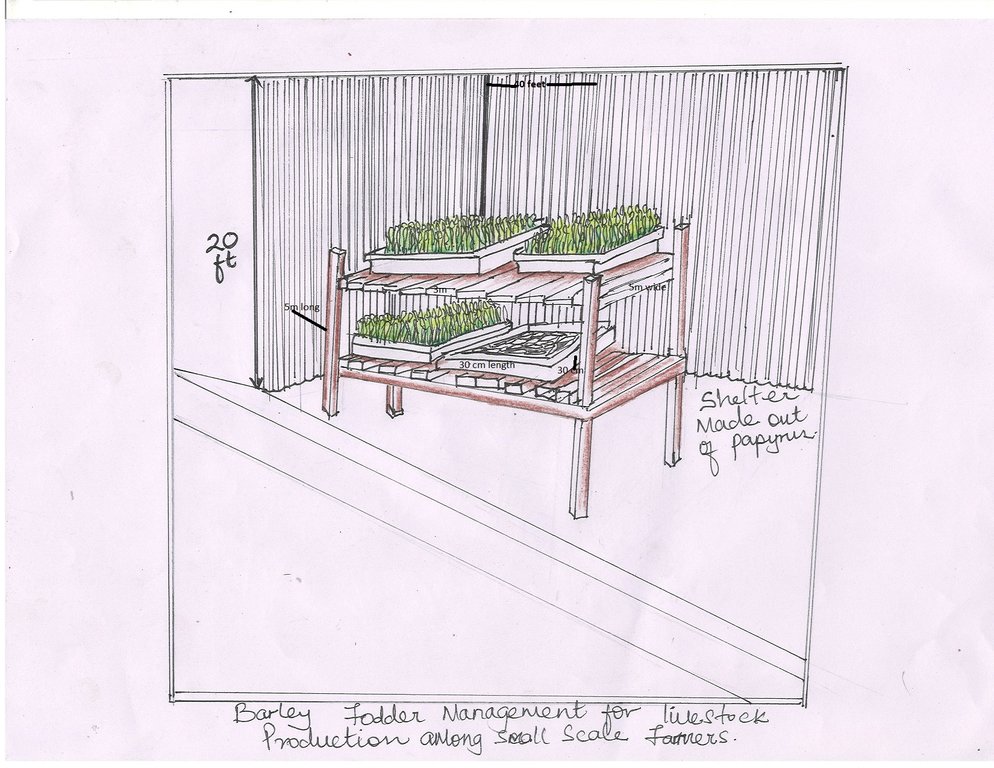

4.1 Technical drawing of the Technology

4.2 Technical specifications/ explanations of technical drawing

The shelter is constructed at 20 feet long and 20 feet wide

Trays(10) of 30cm wide and 30 cm length

Barley seeds (5kg)

Shelves (20) of 3m wide and 3m long

Papyrus mats (2) of 20 feet wide and 40 feet long

Shelves stand of 5m long

4.3 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology unit

Specify volume, length, etc. (if relevant):

20feet long*20feet wide

other/ national currency (specify):

UGX

Indicate exchange rate from USD to local currency (if relevant): 1 USD =:

3600.0

Indicate average wage cost of hired labour per day:

3000/= per day

4.4 Establishment activities

| Activity | Type of measure | Timing | |

|---|---|---|---|

| 1. | Buying seeds | Other measures | Every planting time |

| 2. | Clean the seeds if dirty to avoid molds | Management | Before planting if they are dirty |

| 3. | Soak the seeds for 8-12 hours | Management | 8-12 hours |

| 4. | Place the trays on the shelves | Management | Once from 1-5 day |

| 5. | Water the seeds planted on the tray every 4-8 hours | Management | 4-8 hours for 5 days after planting |

| 6. | Harvest and chop the leaves,stems and roots,then give to the livestock | Agronomic | After harvesting |

4.5 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Making shelves | Man day | 1.0 | 30000.0 | 30000.0 | |

| Labour | Clean the seeds if they are dirty | Man day | 1.0 | 3000.0 | 3000.0 | |

| Labour | Soaking the seeds into water | Man day | 1.0 | 3000.0 | 3000.0 | |

| Labour | Chop the fodder ready for feeding | Man day | 1.0 | 3000.0 | 3000.0 | |

| Equipment | Water the seeds planted on the trey in every 4-8 hours | Man day | 6.0 | 3000.0 | 18000.0 | |

| Equipment | Buying trays | piece | 10.0 | 5000.0 | 50000.0 | |

| Plant material | Buying seeds | Kg | 5.0 | 3000.0 | 15000.0 | |

| Plant material | Buying a watering can | piece | 2.0 | 10000.0 | 20000.0 | |

| Plant material | Buying a bucket | piece | 1.0 | 10000.0 | 10000.0 | |

| Construction material | Timber making shelves | piece | 5.0 | 10000.0 | 50000.0 | |

| Construction material | Nails | Kg | 2.0 | 5000.0 | 10000.0 | |

| Construction material | Papyrus mats | piece | 2.0 | 10000.0 | 20000.0 | |

| Total costs for establishment of the Technology | 232000.0 | |||||

If land user bore less than 100% of costs, indicate who covered the remaining costs:

All costs are covered by the Resource Centre

Comments:

The costs are estimated.

4.6 Maintenance/ recurrent activities

| Activity | Type of measure | Timing/ frequency | |

|---|---|---|---|

| 1. | Watering the seeds | Agronomic | Every day after planting to harvest |

| 2. | Maintaining the room temperature | Agronomic | Every day after planting to harvest |

| 3. | Replacing poles | Structural | Once a year |

| 4. | Cleaning the equipments like treys | Other measures | After harvesting |

| 5. | Replacement of shelves | Structural | Once a year |

Comments:

Maintenance activities are few. Equipments are only replaced when damaged which can take a year.

4.7 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Watering seeds | Man day | 6.0 | 3000.0 | 18000.0 | |

| Labour | Cleaning the equipments( trays) | Man day | 1.0 | 3000.0 | 3000.0 | |

| Equipment | Spervision of the growing barley | Man day | 6.0 | 3000.0 | 18000.0 | |

| Total costs for maintenance of the Technology | 39000.0 | |||||

If land user bore less than 100% of costs, indicate who covered the remaining costs:

The Resource Centre caters for all the costs.

Comments:

These are estimated but almost in the range. This makes the technology more cost efficient.

4.8 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

Labour costs represent the largest cost element.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Agro-climatic zone

- sub-humid

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Indicate if the Technology is specifically applied in:

- not relevant

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

Soil texture (> 20 cm below surface):

- medium (loamy, silty)

Topsoil organic matter:

- medium (1-3%)

5.4 Water availability and quality

Ground water table:

< 5 m

Availability of surface water:

good

Water quality (untreated):

good drinking water

Is water salinity a problem?

No

Is flooding of the area occurring?

No

5.5 Biodiversity

Species diversity:

- medium

Habitat diversity:

- medium

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Sedentary

Market orientation of production system:

- mixed (subsistence/ commercial

Off-farm income:

- 10-50% of all income

Relative level of wealth:

- average

Individuals or groups:

- employee (company, government)

Level of mechanization:

- manual work

Gender:

- men

Age of land users:

- youth

5.7 Average area of land owned or leased by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- small-scale

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- state

Land use rights:

- leased

Water use rights:

- leased

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

fodder quality

Comments/ specify:

Improves on fodder for animals. That is 1 kg of barley yields 7-10 kg of green fodder

animal production

Comments/ specify:

The animals that feed on barley supplements reduced suffering from bloating because of high digestibility

product diversity

Comments/ specify:

Barley is a supplement to the conventional grass

production area

Comments/ specify:

It requires a small production area

land management

Comments/ specify:

Land well managed

Income and costs

farm income

Comments/ specify:

Barley grass is highly nutritious with a lot of protein content. Coupled with being a very palatable fodder, the growth rate of animals increases.

diversity of income sources

Comments/ specify:

One kg of harvested green fodder is sold between 1500-2000/= hence increase in income to a farmer

Socio-cultural impacts

health situation

Comments/ specify:

The health situations of animals is improved. Barley fodder has 95% of the energy and higher digestibility hence reducing the occurrence of digestive diseases, such as bloat. It is one of the most nutritious sprouts and is full of essential nutrients, vitamins and minerals.

6.2 Off-site impacts the Technology has shown

water availability

Comments/ specify:

The technology requires enough supply of water for watering the growing barley

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Climate-related extremes (disasters)

Climatological disasters

| How does the Technology cope with it? | |

|---|---|

| drought | not well at all |

Biological disasters

| How does the Technology cope with it? | |

|---|---|

| insect/ worm infestation | not well at all |

Other climate-related extremes (disasters)

| other (specify) | How does the Technology cope with it? |

|---|---|

| Too high temperature | not well at all |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

very positive

Long-term returns:

very positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

very positive

Long-term returns:

very positive

6.5 Adoption of the Technology

- 10-50%

Of all those who have adopted the Technology, how many have did so spontaneously, i.e. without receiving any material incentives/ payments?

- 10-50%

6.6 Adaptation

Has the Technology been modified recently to adapt to changing conditions?

Yes

If yes, indicate to which changing conditions it was adapted:

- climatic change/ extremes

Specify adaptation of the Technology (design, material/ species, etc.):

It is operated in a moist, cool environment

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| It is less cost effective yet highly nutritious. A kg of barley is nutritionally equivalent to 3Kg of other grass like the lucerne. |

| Barley grows in a very short period of time |

| It requires a small piece of area to grow barley |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| Barley improves the overall health and well-being of animals |

| It has higher digestibility hence reduces on some diseases like bloat |

| Barley growing does not involve the use of soil hence cost effective |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| The technology requires skills and knowledge especially to manage the conditions for growth | Encouraging farmers to train from model farmers |

| Barley seeds are at times hard to get. | Promoting the barley seed multiplication in large quantities |

| The technology requires maximum supervision | Always endeavor to do maximum supervision |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| Bacterial and fungal growth is also another challenge e.g the common bread mould. | Seeds must be sterilized |

| Barley is not economically feasible for large scale farmers on pasture production | To grow more pastures in addition to barley as feed supplements |

| It cannot be stored for a long period of time | Serve it in the first days after harvest. |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

2

- interviews with land users

2

- interviews with SLM specialists/ experts

7.2 References to available publications

Title, author, year, ISBN:

Growing Sprouted Fodder For Livestock by Jason Wiskerchen Monday, March 19, 2012,

Available from where? Costs?

https://www.peakprosperity.com/growing-sprouted-fodder-for-livestock-2/

7.3 Links to relevant information which is available online

Title/ description:

https://www.hydroponics-simplified.com/hydroponic-fodder-advantages.html

URL:

http://www.fodderconsultants.com/advantages.html

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules