Irrigation of uplands through Hydraulic Flange Pump [Afghanistan]

- Creation:

- Update:

- Compiler: Aqila Haidery

- Editor: –

- Reviewers: Alexandra Gavilano, David Streiff, Joana Eichenberger

Aabyari zamin hai boland Aaba thawasut Pump_e_Aabi_Charkhdar

technologies_1731 - Afghanistan

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

SLM specialist:

SLM specialist:

SLM specialist:

Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

HELVETAS (Swiss Intercooperation)Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

People in Need (PIN) (People in Need (PIN)) - Afghanistan1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

Technology for lifting water to uplands: hydraulic flange pump, reservoir and pipe scheme.

2.2 Detailed description of the Technology

Description:

This technology is documented by the Sustainable Land Management Project, implemented by HELVETAS Swiss Intercooperation and funded by the Swiss Agency for Development and Cooperation (SDC), with close support and cooperation of People in Need.

Samangan, Khuram wa Sarbagh district, Klor-e-Bala village is situated in a mountainous region where the greatest limiting factor to agricultural production is water. Arable lands are located far away from water sources. Lack of technology to exploit these lands prohibits villagers to cultivate their land to make a livelihood. Therefore, families are compelled to leave their village during summer.

Purpose of the Technology: To address this problem, People in Need (PIN), with financial support from GIZ and the Czech Embassy (CzDA) introduced irrigation through hydraulic flange pump. The hydraulic flange pump provides water to 30 orchards of Klor-e-Bala village, drinking water to the 43 village households, the mosque and the school of 500 students.

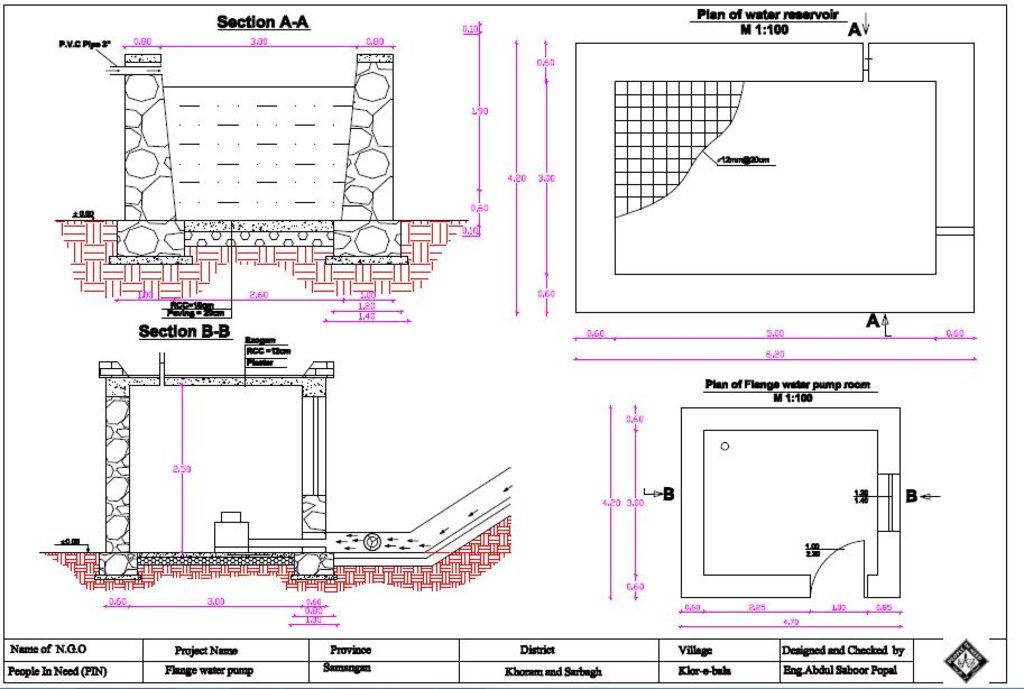

Establishment / maintenance activities and inputs: The main water source which starts and runs the hydraulic flange pump is the Khuwaja Hayat spring. The spring water arrives to the hydraulic flange pump from 1.8 meter height on a 12 percent slope in 200 meters distance from the water source. The water flow passes through the intake and moves towards the water wheel which starts/runs the hydraulic flange pump. The water is then pumped through three pipes of one inch to the reservoir. The hydraulic flange pump has the capacity of lifting water up to 250 meters.

The reservoir’s storage capacity is 25,600 liters of water with the dimensions as follows: 4.9 meter length; 2.9 m width; and 1.8 m height. It has two outlets: a spill way fitted with three pipes of one inch at the top of the reservoir and two outlets fitted with two pipes of three inches at the bottom. The lower outlet leads water to the orchards by diverting water after 40 meters into two pipes which are 1,000 meters long. Each orchard is connected to one of these two pipes by a T-connector and the water flows into a tin water tank with the capacity of 1,000 liters for each orchard. The two pipes are extended as far as the school which is located near the orchards and has been equipped with a 2000 liters tin water tank.

The hydraulic flange pump is made locally in Taloqan city, Takhar province of Afghanistan in the Baradaran-e- Kargar workshop. The pump costs 140,000 Afghani/ 2,200 US$, including installment. The estimated cost of the construction of the reservoir and the pump’s room including the hydraulic flange pump is 19,000 US$. The pipe scheme of the project was installed by the Community Development Council (CDC) with technical support from PIN’s engineering team. Community members contributed 10 percent of the costs as labor. As Klor-e-Bala village is situated in flood prone area and flooding is a common occurrence, PIN, with funding from the GIZ, constructed in 2015 two protection walls, 45 m and 55 m in length, on both sides of the river, to minimize erosion and protect the pump’s intake from floods. The protection walls were built through cash for work programme, but community members provided 10 percent contribution through labor and by providing stones for construction. The total estimated cost of the hydraulic flange pump, reservoir and pipe scheme technology amounted to 37,000 US$.

Furthermore, in order to maintain the technology, a caretaker, who lives close to the pump’s room has been appointed. The caretaker was trained by the technician who installed the hydraulic flange pump and has voluntarily taken the responsibility of maintenance activities; changing the oil and cleaning of the hydraulic flange pump's room and changing of the pipes in case of need. The owners of the orchards have to cover for all maintenance costs and the chairman of the Community Development Council (CDC) has the responsibility of managing the money for maintenance and other recurrent activities.

The flange pump technology contributed to the economic growth of the community members by increasing the orchards’ yields. Currently, the hydraulic flange pump irrigates 12 jireb/2.4 ha (30*800m2) orchards of apple, apricot, almond, pear and cherry trees. In addition to the orchards, alfalfa, potato, vegetables and other crops are as well cultivated on these lands. Furthermore, the pump supports the community members to settle year-round in their villages and prevents from their seasonal displacement. Moreover, the flange pump enables the provision of drinking water to the whole community and the school.

Natural / human environment: Samangan is one of the northern provinces of Afghanistan. Wheat, melons, pistachio,

almonds, potatoes, onions and caraway are important crops and Karakul sheep

and goats the main livestock for meat, dairy, and wool production. Rugs are the

main handicraft of this area. Khuram-wa-Sarbagh district in Samangan has two growing

seasons, the longest of which is 150 days from February to June and the second is 90

days from June to September. The average rainfall is below 500mm and the climate semi-arid.

The community members have limited access to off farm employment, market, energy,

financial services, roads and transportation and moderate access to health and education.

2.3 Photos of the Technology

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Afghanistan

Region/ State/ Province:

Samangan

Further specification of location:

Khuram-wa-Sarbagh district, Klor_e_Bala village

Specify the spread of the Technology:

- evenly spread over an area

If precise area is not known, indicate approximate area covered:

- 1-10 km2

Comments:

The technology area which is considered here is the distance from the water area where the machine exists to the reservoir and reservoir to the orchard and crop land.

2.6 Date of implementation

If precise year is not known, indicate approximate date:

- less than 10 years ago (recently)

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through projects/ external interventions

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- access to water

3.2 Current land use type(s) where the Technology is applied

Land use mixed within the same land unit:

Yes

Specify mixed land use (crops/ grazing/ trees):

- Agroforestry

Cropland

- Annual cropping

- Tree and shrub cropping

Number of growing seasons per year:

- 2

Specify:

Longest growing period in days: 150; Longest growing period from month to month: February - June; Second longest growing period in days: 90; Second longest growing period from month to month: June - September

Grazing land

Comments:

Major land use problems (compiler’s opinion): Lack of safe drinking and irrigation water which makes agricultural activities difficult.

Major land use problems (land users’ perception): Lack of cultivation due to the scarcity of water. High workloads and small incomes.

Future (final) land use (after implementation of SLM Technology): Mixed: Mf: Agroforestry

3.3 Has land use changed due to the implementation of the Technology?

Has land use changed due to the implementation of the Technology?

- Yes (Please fill out the questions below with regard to the land use before implementation of the Technology)

Waterways, waterbodies, wetlands

- Drainage lines, waterways

- Ponds, dams

3.4 Water supply

Water supply for the land on which the Technology is applied:

- rainfed

3.5 SLM group to which the Technology belongs

- natural and semi-natural forest management

- agroforestry

- irrigation management (incl. water supply, drainage)

3.6 SLM measures comprising the Technology

structural measures

- S5: Dams, pans, ponds

3.7 Main types of land degradation addressed by the Technology

biological degradation

- Bc: reduction of vegetation cover

- Bq: quantity/ biomass decline

Comments:

Secondary types of degradation addressed: Bq: quantity / biomass decline

Main causes of degradation: disturbance of water cycle (infiltration / runoff), droughts, education, access to knowledge and support services

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- restore/ rehabilitate severely degraded land

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

A detailed technical drawing of the hydraulic flange pump and the reservoir, Klor-e-Bala village, Khuram-wa-Sarbagh district, Samangan province.

Technical knowledge required for field staff / advisors: high

Technical knowledge required for land users: moderate

Main technical functions: improvement of ground cover, improvement of surface structure (crusting, sealing), improvement of topsoil structure (compaction), stabilisation of soil (eg by tree roots against land slides), water harvesting / increase water supply, water spreading

Author:

Eng. Saboor Popal, People In Need (PIN)

4.2 General information regarding the calculation of inputs and costs

Specify currency used for cost calculations:

- USD

Indicate average wage cost of hired labour per day:

7.00

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Excavation of the foundation | |

| 2. | Construction activities,Stone masonry foundation and wall: | |

| 3. | a:P.C.C concrete foundationb:R.C.C concretec:Iron shattering for walls, roof and floord:External and internal pointing | |

| 4. | a:Plasteringb:Steel barsc:Door and window | |

| 5. | Pipe scheme:a:Pipesb:Water tanksc:other equipmentd:Skilled and unskilled labor | |

| 6. | Procurement of the Hydraulic flange pump |

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Excavation of the foundation | square meters | 50.0 | 2.88 | 144.0 | 10.0 |

| Labour | Excavation of the foundation | cubic meters | 161.0 | 2.4037 | 387.0 | 10.0 |

| Labour | Skilled and unskilled labor | persons/day | 343.0 | 9.47521 | 3250.0 | 10.0 |

| Equipment | Water tanks | pieces | 39.0 | 98.615384 | 3846.0 | 10.0 |

| Equipment | Pipes | meter | 2900.0 | 2.9241379 | 8480.0 | 10.0 |

| Equipment | Other equipment | all | 1.0 | 2424.0 | 2424.0 | 10.0 |

| Equipment | Procurement of the Hydraulic flange pump | pieces | 1.0 | 2200.0 | 2200.0 | 10.0 |

| Construction material | Concrete foundation | cubic meters | 12.23 | 96.64758 | 1182.0 | 10.0 |

| Construction material | Concrete | cubic meters | 8.4 | 114.0476 | 958.0 | 10.0 |

| Construction material | Iron shattering for walls, roof and floor | cubic meters | 110.0 | 4.86363 | 535.0 | 10.0 |

| Construction material | External and internal pointing | square meters | 226.0 | 2.85398 | 645.0 | 10.0 |

| Construction material | Plastering | square meters | 32.0 | 5.9375 | 190.0 | 10.0 |

| Construction material | Steel bars | square meters | 364.4 | 1.21844 | 444.0 | 10.0 |

| Construction material | Door and window | square meters | 3.98 | 28.8944 | 115.0 | 10.0 |

| Construction material | Stones | square meters | 244.0 | 50.0 | 12200.0 | 10.0 |

| Total costs for establishment of the Technology | 37000.0 | |||||

| Total costs for establishment of the Technology in USD | 37000.0 | |||||

Comments:

Duration of establishment phase: 7 month(s)

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | Changing of the pipes | Once a year |

| 2. | Cleaning of the flange pump room | Six times a year |

| 3. | Changing of the hydraulic flange pump oil |

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Changing of the pipes | persons/day | 1.0 | 7.0 | 7.0 | 100.0 |

| Labour | Cleaning of the flange pump room | persons/day | 1.0 | 7.0 | 7.0 | 100.0 |

| Labour | Changing of the hydraulic flange pump oil | persons/day | 1.0 | 7.0 | 7.0 | 100.0 |

| Equipment | Pipes | meter | 20.0 | 0.65 | 13.0 | 100.0 |

| Equipment | Oil | times/year | 4.0 | 4.5 | 18.0 | 100.0 |

| Total costs for maintenance of the Technology | 52.0 | |||||

| Total costs for maintenance of the Technology in USD | 52.0 | |||||

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

Labor, stone and equipment are the main fundamental factors which need high initial investments.

After a couple of years pipes may need to be changed.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Agro-climatic zone

- semi-arid

Thermal climate class: temperate

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- coarse/ light (sandy)

Topsoil organic matter:

- low (<1%)

If available, attach full soil description or specify the available information, e.g. soil type, soil PH/ acidity, Cation Exchange Capacity, nitrogen, salinity etc.

Soil fertility is medium

Soil drainage / infiltration is medium

Soil water storage capacity is low

5.4 Water availability and quality

Ground water table:

5-50 m

Availability of surface water:

medium

Water quality (untreated):

good drinking water

5.5 Biodiversity

Species diversity:

- medium

Habitat diversity:

- medium

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Nomadic

Off-farm income:

- 10-50% of all income

Relative level of wealth:

- poor

Individuals or groups:

- groups/ community

Gender:

- men

Indicate other relevant characteristics of the land users:

Land users applying the Technology are mainly disadvantaged land users

Difference in the involvement of women and men: Constructional activities which are done outside of the houses and compounds are mainly applied by men in Afghanistan.

Population density: 10-50 persons/km2

Annual population growth: 2% - 3%

100% of the land users are poor.

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- small-scale

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- communal/ village

Land use rights:

- communal (organized)

Water use rights:

- communal (organized)

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

fodder production

fodder quality

product diversity

production area

land management

Water availability and quality

drinking water availability

water availability for livestock

water quality for livestock

irrigation water availability

irrigation water quality

Income and costs

expenses on agricultural inputs

farm income

diversity of income sources

workload

Socio-cultural impacts

food security/ self-sufficiency

health situation

SLM/ land degradation knowledge

conflict mitigation

Comments/ specify:

In case the owner of the first orchard do not obey the water use right

livelihood and human well-being

Comments/ specify:

The pump improved households’ economy through increasing agricultural yieIds and by decreasing the need for a generator pump. It has as well reduced the workload of the community members

Ecological impacts

Water cycle/ runoff

harvesting/ collection of water

evaporation

Soil

soil moisture

soil cover

soil crusting/ sealing

soil compaction

salinity

Biodiversity: vegetation, animals

plant diversity

animal diversity

Climate and disaster risk reduction

flood impacts

6.2 Off-site impacts the Technology has shown

water availability

Comments/ specify:

It has decreased the water flow only in the place where the hydraulic flange pump is installed.

reliable and stable stream flows in dry season

groundwater/ river pollution

buffering/ filtering capacity

damage on neighbours' fields

damage on public/ private infrastructure

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | increase or decrease | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | well | |

| annual rainfall | increase | well |

Climate-related extremes (disasters)

Meteorological disasters

| How does the Technology cope with it? | |

|---|---|

| local rainstorm | not known |

| local windstorm | not well |

Climatological disasters

| How does the Technology cope with it? | |

|---|---|

| drought | well |

Hydrological disasters

| How does the Technology cope with it? | |

|---|---|

| flash flood | not well |

Other climate-related extremes (disasters)

| other (specify) | How does the Technology cope with it? |

|---|---|

| length of growing period | well |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

very negative

Long-term returns:

slightly positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

neutral/ balanced

Long-term returns:

positive

6.5 Adoption of the Technology

- 11-50%

If available, quantify (no. of households and/ or area covered):

98 households covering 50 percent of the stated area

Of all those who have adopted the Technology, how many did so spontaneously, i.e. without receiving any material incentives/ payments?

- 0-10%

Comments:

98 land user families have adopted the Technology with external material support

Comments on spontaneous adoption: Due to high expenses of the implementation of the technology, it has not been applied without any external support.

There is a little trend towards spontaneous adoption of the Technology

Comments on adoption trend: The technology is of a high cost and needs external support to be established.

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

|

Application of the technology has reduced the workload for the families. How can they be sustained / enhanced? Greater awareness on water management can be created by training/workshop for the water users. |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

|

The technology has supported the community members economically by increasing agricultural yields. Moreover, it contributes to reduce the costs of water during the summer season. How can they be sustained / enhanced? The land users should try to plant local and native trees and cultivate the crops which are adapted to the land.Community members should actively participate in maintenance activities. |

|

Provides safe drinking water to the 43 households and the school at low cost. How can they be sustained / enhanced? Pipe scheme and cover of the reservoir, should be cleaned regularly. If any leakages occurs in the pipes or reservoir, they should be sealed. Water taps and water tanks should be properly maintained. |

|

This technology has been applied in a low slope/latitude where the water flows with a very low speed and the application of other technologies was difficult. How can they be sustained / enhanced? Protect from sedimentation. |

|

The hydraulic flange pump is produced locally. Procurement and installment of the pump contributes therefore to local economic growth and private sector development. How can they be sustained / enhanced? Link the company to the other potential buyers. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| Social conflicts can occur during the distribution of water | The water in keeper/maintainer can be introduced by CDCs for the distribution of water. |

| Electricity cannot be produced by applying this technology. The slope and latitude of the location where the flange pump is installed is too small. |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

|

It is difficult to apply the technology without any external and financial support. |

Locally available materials should be used to reduce costs. |

| High level of technical knowledge is required for the establishment of the technology. | The technical knowledge should be transferred to the extension workers or local people to provide technical support in the future. |

|

This technology needs regular maintenance and the reservoir has to be properly cleaned after heavy rainfalls. |

The CDC should monitor maintenance activities by the caretaker as well as manage funds for maintenance costs. |

7. References and links

7.1 Methods/ sources of information

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules